1. What is IO-Link?

2. Benefits of IO-Link

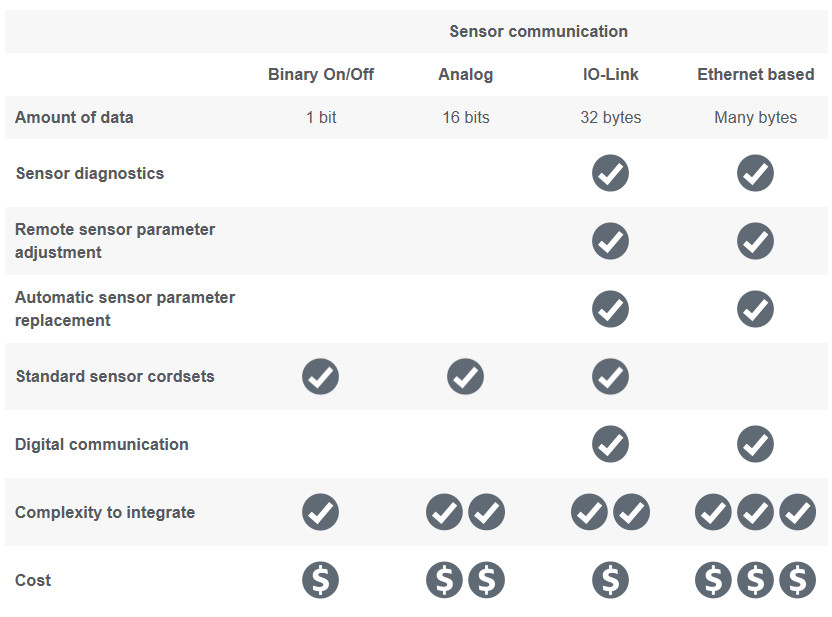

2. Comparisons

4. How does the IO-Link work?

4. Conclusion

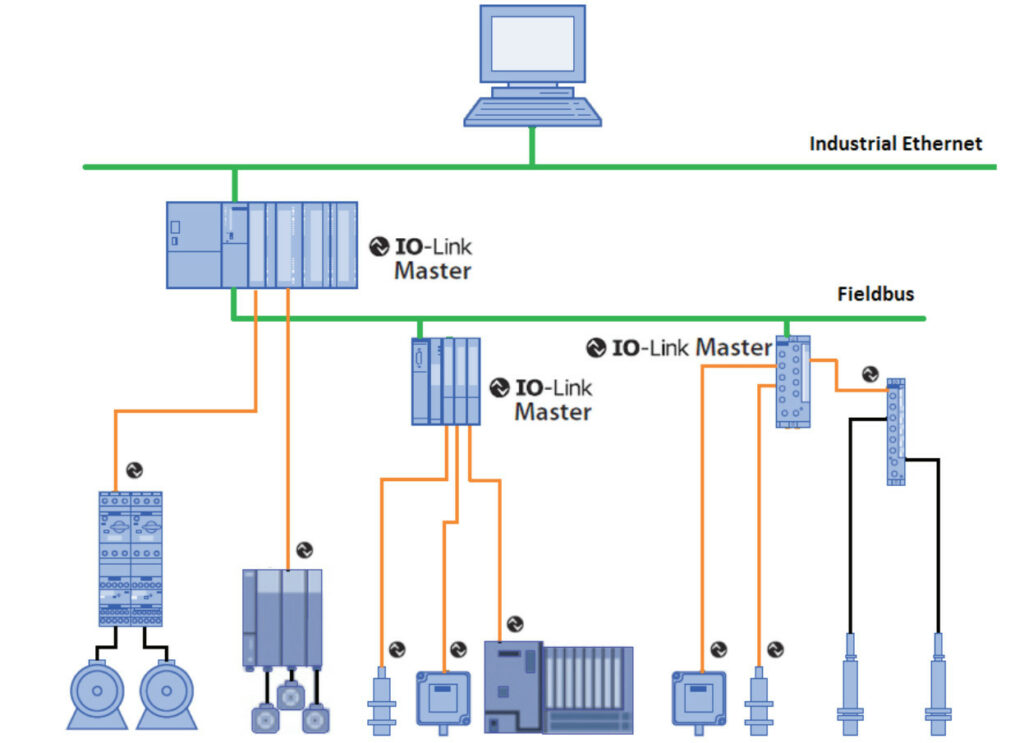

1. What is IO-Link?

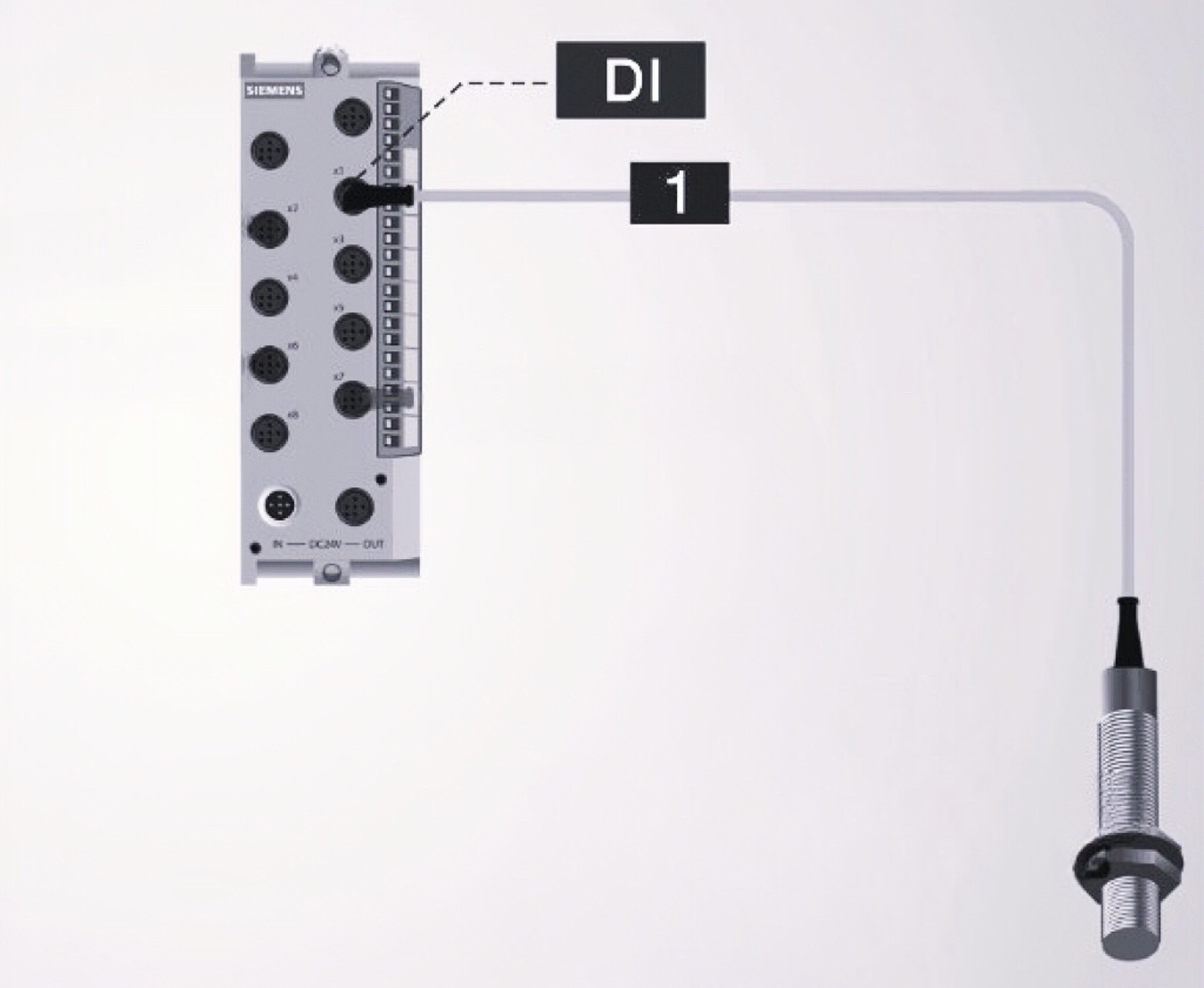

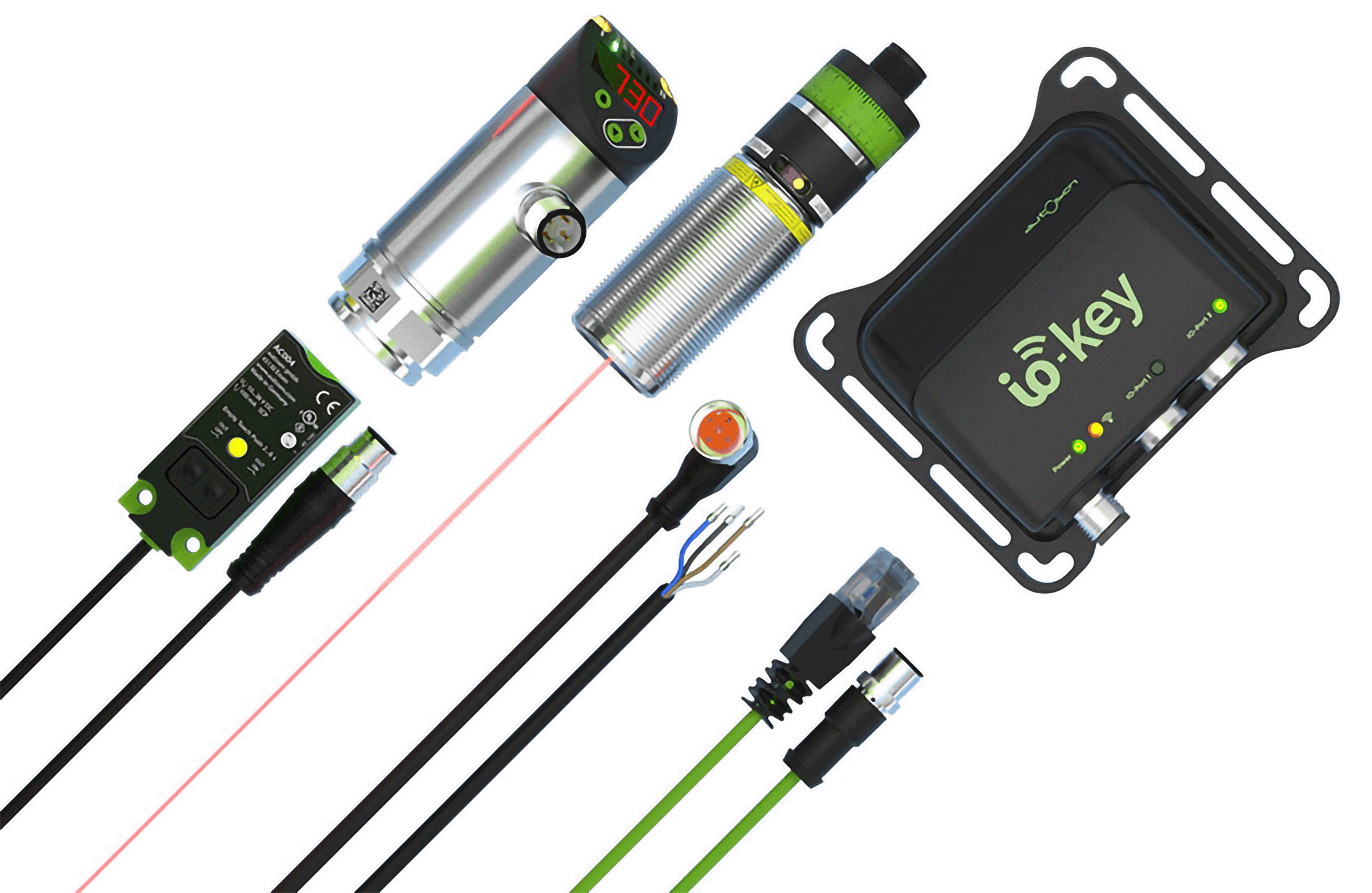

Example of system architecture with IO-Link

IO-Link uses standard 3-wire or 4-wire, unshielded sensor cables up to 20 meters.

Provides a true digital process value that is a lower-cost alternative to analog signals.

IO-Link provides Device identifications, Process value valid, Overload conditions, …

2. Benefits of IO-Link

The IO-Link system offers the following benefits for the connection of complex sensors/actuators:

- Improved product quality

100% digital communication is more reliable and accurate than an analog signal. And, predictive information from sensors improves product quality and instrument verification processes.

- Low costs

Reduce expenses by eliminating analog input cards and reducing the size of control cabinets.

- Increased efficiency

Reduce cycle time for recipe changes with bidirectional communication between process instruments and a higher-level controller.

- Improve machine uptime

With the automatic device replacement feature of IO-Link enabled sensors, parameters from an existing device are automatically downloaded onto the replacement device. This minimizes unplanned downtime and gets your machine up and running faster.

- Reduced complexity

Scalable technology from simple binary On/Off devices up to smart IO-Link enabled sensors provide complete process transparency that quickly integrates into existing controls architecture.

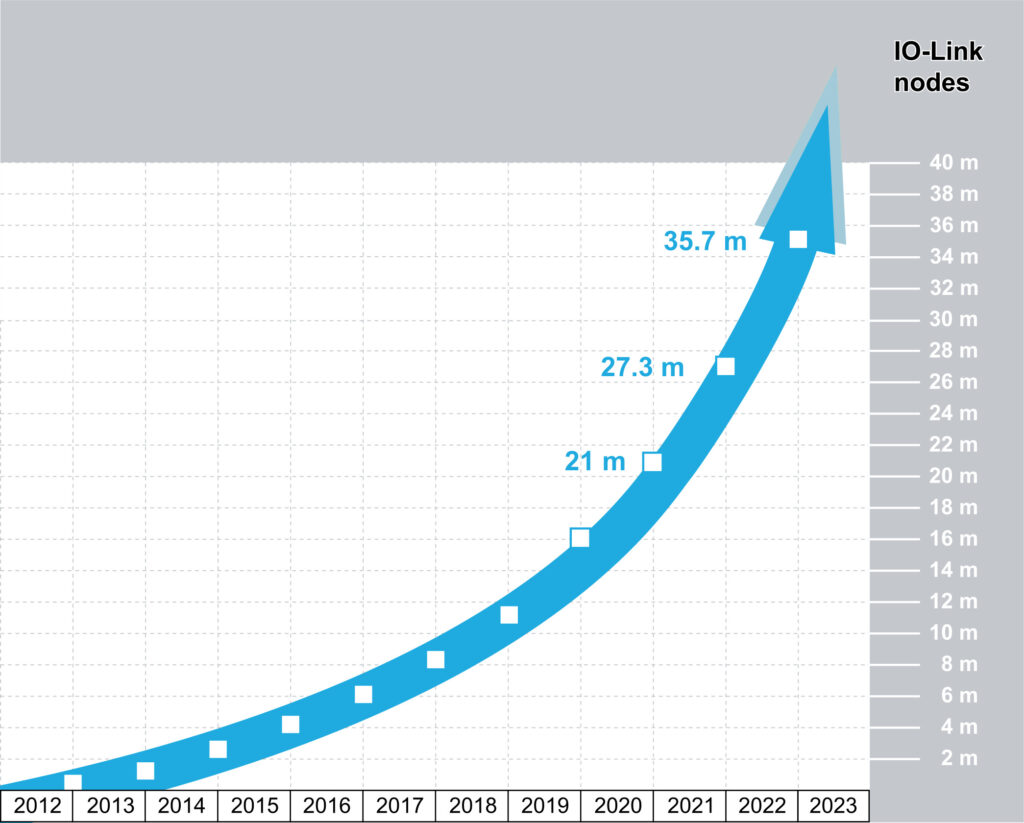

IO-Link has grown exponentially over the last decade

3. Comparisons to other communication technologies

IO-Link vs. Standard Analog Wiring

Analog systems are still in use at many facilities and are less expensive to install than IO-Link. However, they suffer from data losses when the signal converts from analog to digital so it can integrate with modern software. The data losses become more severe in setups with multiple conversion points. IO-Link is fully digital, avoiding any data losses even connections span large distances.

IO-Link vs. HART

HART protocol is well-known, especially in the food and beverage, pharmaceutical, and chemical industries. Like IO-Link, it provides bidirectional communication of data between sensors and the control system. Digital and analog signals are transmitted over cables. Integrating HART requires specific programming knowledge.

4. How does the IO-Link work?

IO-Link is a point-to-point communication protocol. A point-to-point connection is a communications connection between two separate endpoints or nodes. It is bi-directional, meaning it works two ways and works over a short distance.

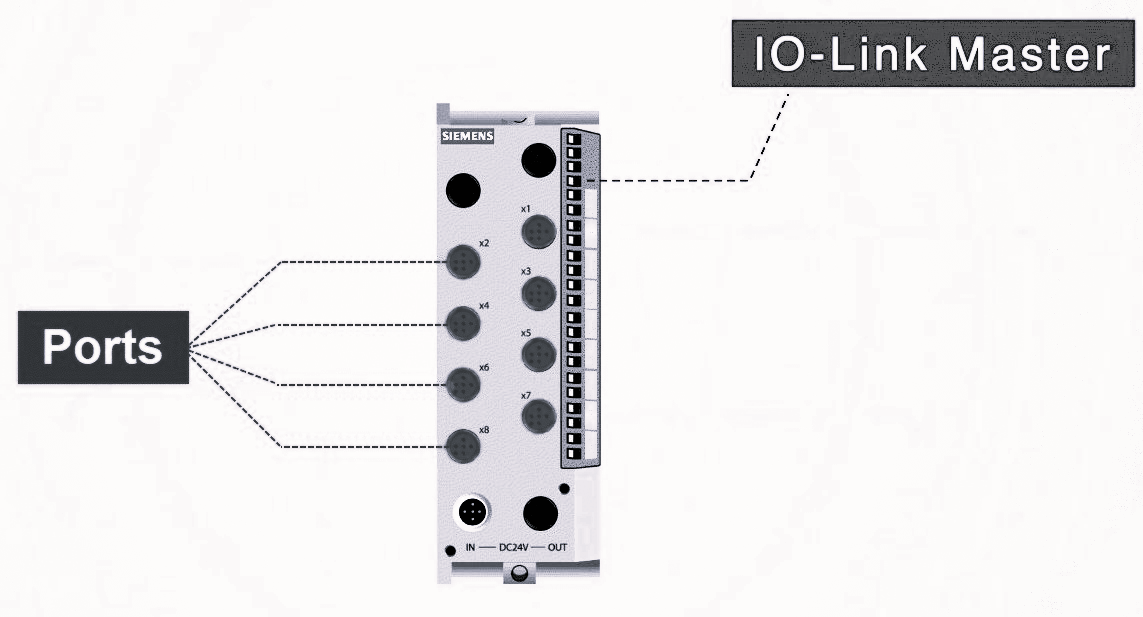

An IO-Link master can have several ports or channels.

An IO-Link device can be connected to each port, meaning IO-Link is a point-to-point communication.

IO-Link Master

IO-Link Operating Modes

- IO-Link Mode: The port is used for IO-Link communication.

2. DI Operating Mode: The port acts in the same way as a digital input device.

3. DQ Operating Mode: The port acts in the same way as a digital output device.

4. Deactivated Operating Mode: The port is not assigned to any other modes and is reserved for when the port is unused

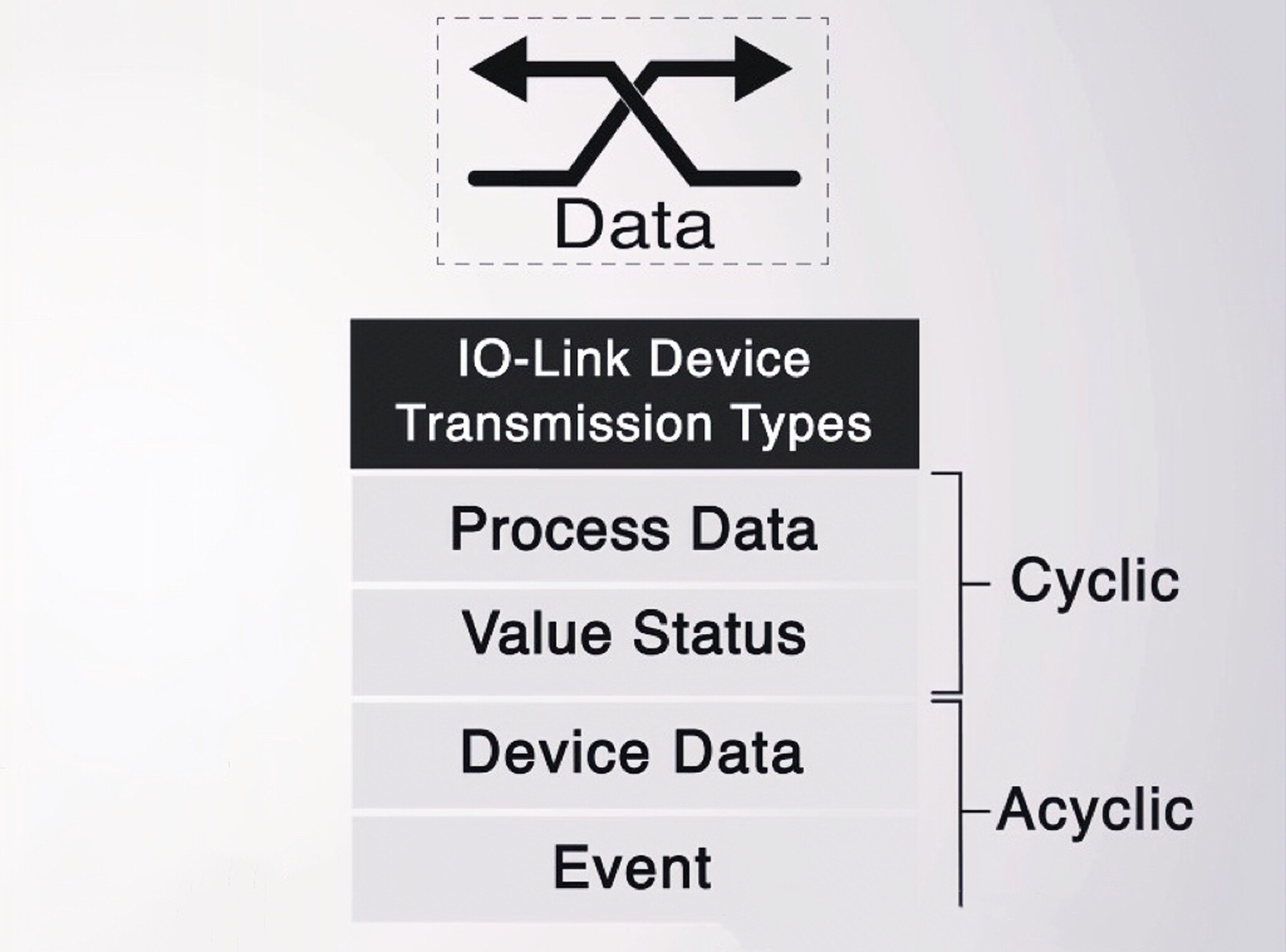

IO-Link Transmission Types

1. IO-Link Process Data Transmission:

- The Process Data is considered the latest state of the sensor or actuator.

- Process Data is transmitted cyclically, up to 32 bytes of process data can be processed.

2. IO-Link Value Status Transmission:

- The Value Status indicates whether the Process Data is valid or invalid

- The Value Status is transmitted along with the Process Data cyclically.

3. IO-Link Device Data Transmission

- The Device Data holds detailed information about a device.

- Device Data is transmitted acyclically, at the request of the IO-Link master.

- Device Data can be read from the device, but also written to.

4. IO-Link Event Transmission

- A device can trigger an Event.

- An example of an event is an error or warning message.

- Events occur independently from the cyclic transmission of Process Data.

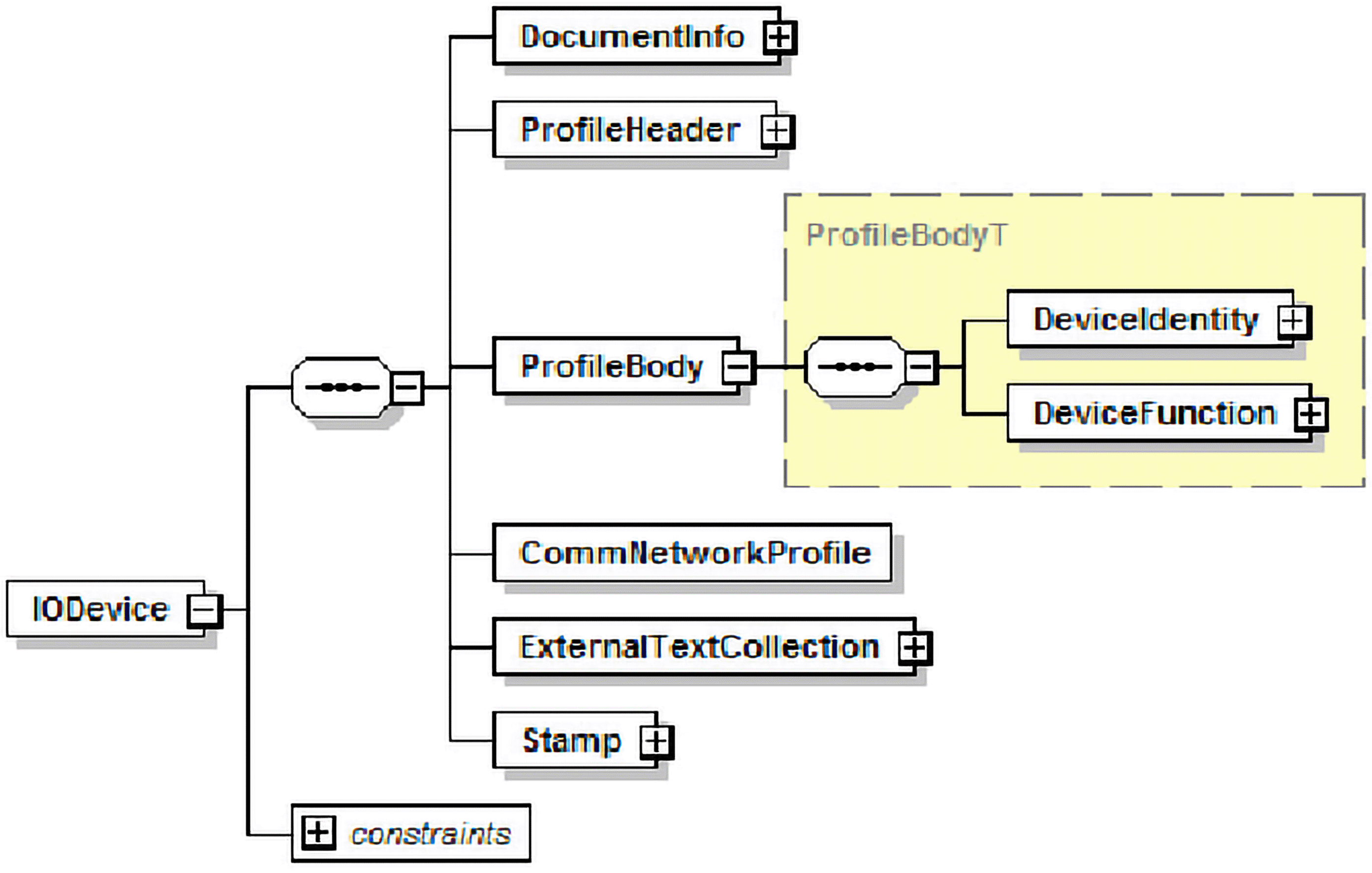

IO-Link Device Profile

Each IO-Link device has an IO device description (IODD) that specifies the data structure, data contents, and basic functionality – providing a uniform description and access for software and controllers. The user can easily read and process this information.

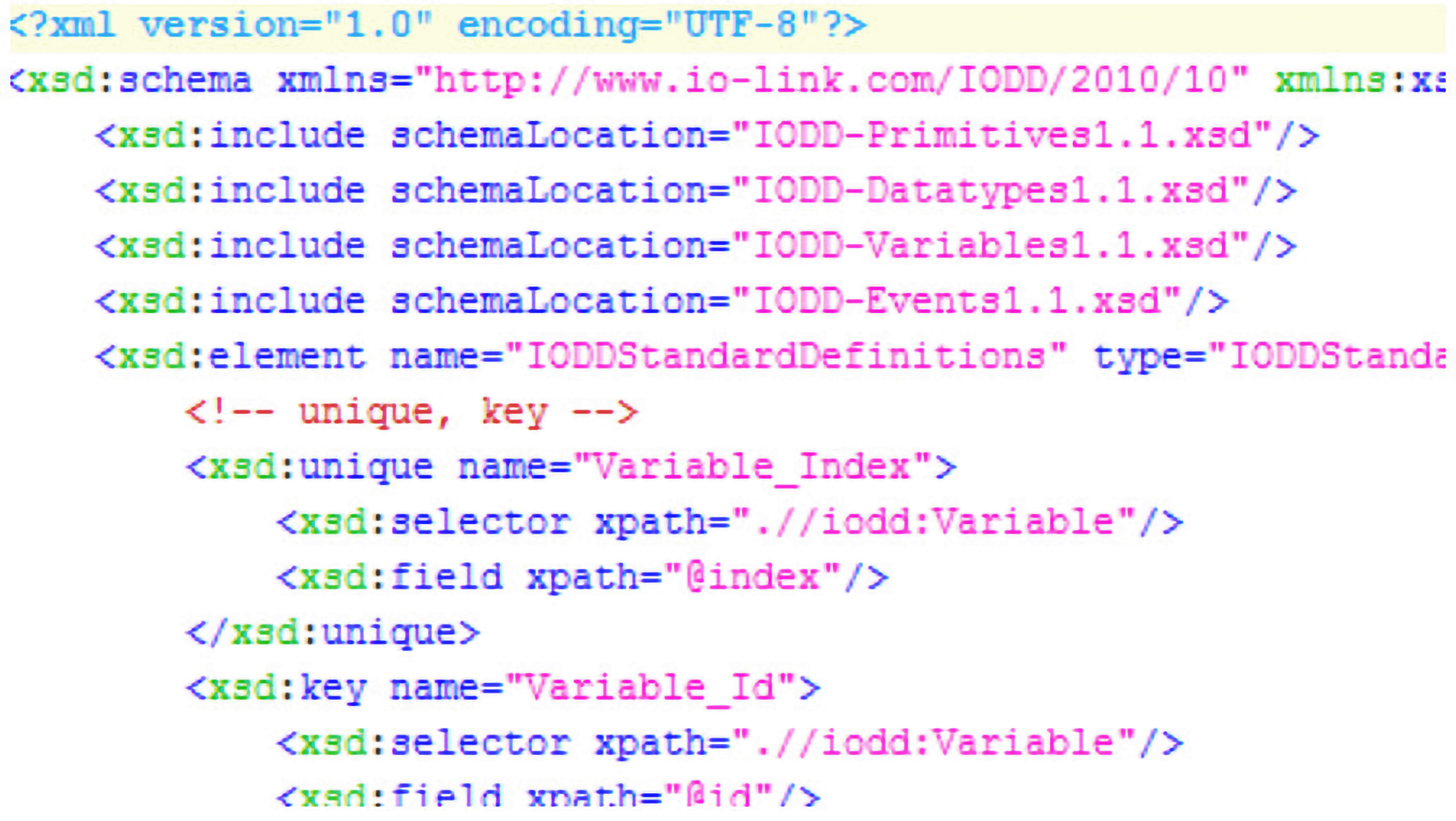

IODD Structure

The IODD is an electronic data definition that is one or several XML files describing the device, manufacturer-specific properties, and image files in the PNG format. According to the IO-Link organization, this information can be easily read and processed by the user because it is in XML format.

IODD XML Format

If you’re seeking a streamlined solution to enhance the communication between your io-link devices, consider exploring iokey device – An all-in-one solution consisting of a wireless gateway, cloud access, and data flat rate, which enables sensor data to be brought into the cloud, monitored and analyzed easily and in a matter of seconds

5. Conclusion

Thank you for exploring our article on IO-Link! We trust that you’ve gained valuable insights. We hope you found it informative. Should you require any assistance, consultation, or support related to IO-Link, consider reaching out to us via [email protected]